What type of fitment do you have?

Search by vehicle:

Search by size:

It’s the GT Radial way—get more out of every road, every ride, every day, every dollar. And it’s part of every GT Radial tire.

With more than 25 years in North America, GT Radial offers a complete line of tires for virtually every kind of passenger vehicle, from ultra high performance cars to luxury touring sedans and crossovers to SUV and light trucks.

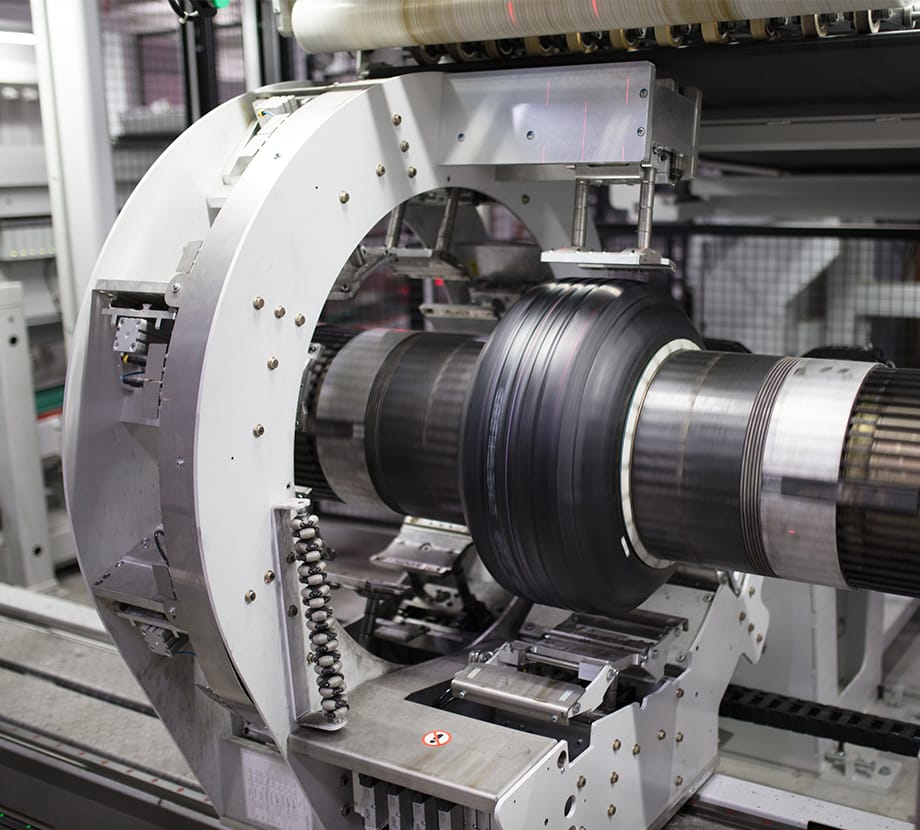

Designed and developed with world class technology and quality, GT Radial tires are manufactured by Giti Tire, a leading global tire company serving consumers in over 130 countries around the world. In addition to seven state-of-the-art manufacturing facilities across the globe, a new US plant began production in 2017.

GT Radial tires are available from leading independent tire dealers around the country. Begin your journey and find a GT Radial dealer so you can “Experience the Performance” of GT Radial tires for yourself!

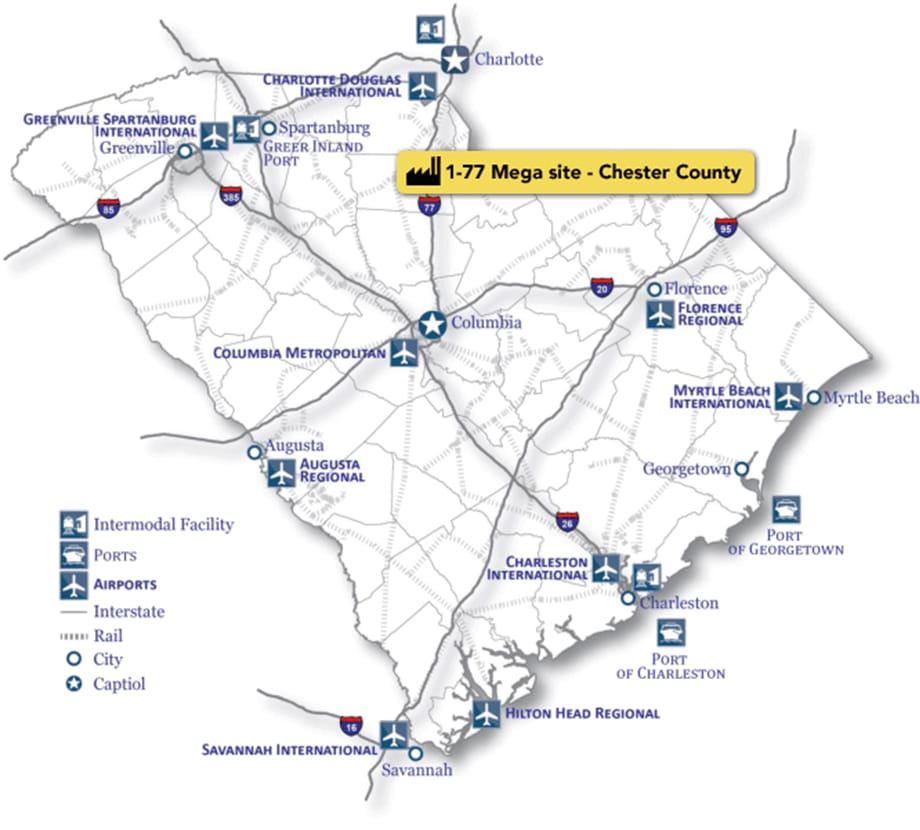

The 1,100+ acre site is located in Chester County, South Carolina. The state-of-the-art manufacturing plant and distribution center began production in October, 2017. The facility will combine a state-of-the-art manufacturing facility and distribution center. The project is expected to create 1,700 new jobs over the next 10 years. Giti Tire will invest approximately $560 million dollars.

As the first manufacturing facility in North America for Giti Tire, this will be Giti’s 9th tire manufacturing plant globally. The new facility will produce PCR/LT tires for the replacement market and automakers in North America.

What type of fitment do you have?

Search by vehicle:

Search by size:

© GT Radial. All Rights Reserved.